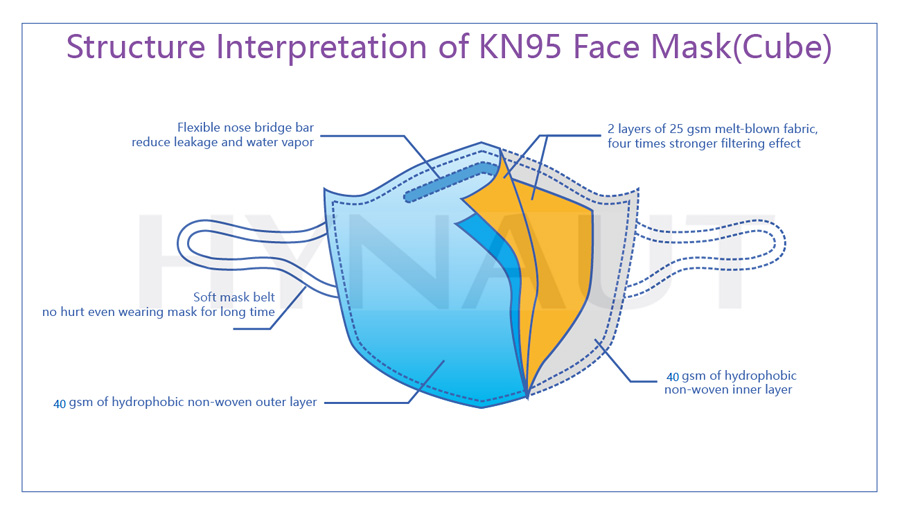

Melt-blown fabric is made of polypropylene;Which consisting of many crisscrossed fibers;And formed the film layered in random directions;The fiber diameter ranges from 0.5~10 μm.

High voidage, fluffy structure, good anti-fold ability; Good filtering, shielding, thermal insulation, oil absorption; Formed the core of face mask manufacture.

The random distribution of the fibers give more opportunities for thermal bonding between fibers,made filter material has larger specific surface area and higher porosity.

After the high pressure electret filtration, the product has the characteristics of low resistance, high efficiency and high dust capacity.

Whether the mask is qualified depends largely on the melt-blown fabric;The testing of melt-blown fabric is mainly contains particle filtration efficiency test and bacterial filtration efficiency test.

Haishi Hainuo Group has advanced workshops, logistics and warehousing facilities in line with international standards, inside of which also equipped with international advanced production equipment and sophisticated testing instruments.At present, the whole industry chain of “Melt-blown Fabric Production Line + Face Mask Production Line + Third-party Testing Service” has been formed.At the same time, the introduction of internationally advanced fully automated melt-blown fabric production equipment, realized of 10 tons daily melt-blown output as well as totally 5,000,000 daily masks production.

HYNAUT Melt-blown Workshop: